Our gears are engineered using advanced machining methods to deliver silent operation, high

torque capacity, and exceptional accuracy across multiple industrial applications.

Spur Gear

● Simple and efficient design

● Ideal for high-speed, low-noise applications

● High load-carrying capacity

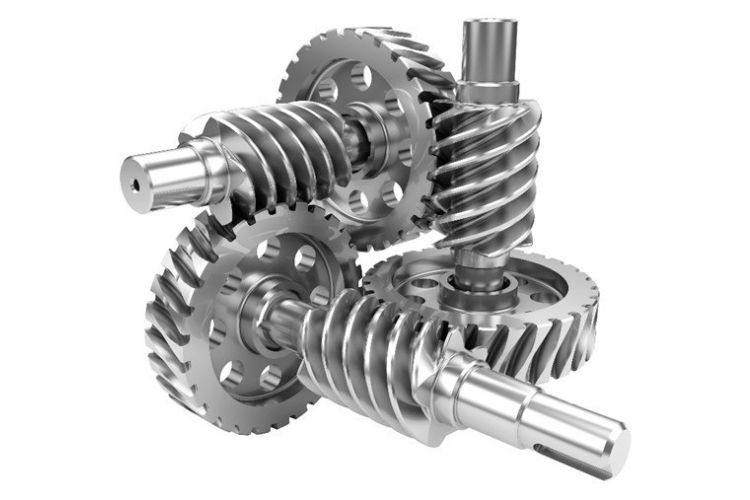

Worm Gear

● High reduction ratios

● Self-locking capability for safety

● Smooth and quiet operation

Commonly used in lifts, hoists, and compact drive systems.

Spiral Bevel Gear

● Precise angular power transmission

● Smooth, vibration-free performance

● High efficiency at variable speeds

Used in heavy machinery, conveyors, and automation equipment.

Helical Gear Pair

● Helical teeth ensure quieter operation

● Handles higher loads than spur gears

● Better meshing and increased operational life – Ideal for industrial gearboxes and

high-performance drives.

Gears

Material : EN8 / EN24 / Cast Iron

Module Range : 1–12 Module

Face Width : 8–100 mm

Teeth Hardness : 40–55 HRC

Pressure Angle : 20° / 25°

Applications : Power transmission, medium-speed

gearboxes

Worm Gear

Material : Bronze worm wheel, EN24 worm shaft

Reduction Ratio : 10:1 to 60:1

Efficiency : 40–90%

Mounting : Vertical / Horizontal

Applications : Lifts, conveyors, compact drives

Spiral Bevel Gear

Material : Alloy Steel

Module Range : 2–10 Module

Hardness : Up to 60 HRC (case

hardened)

Angle Accuracy : ±5 arc minutes

Applications : Angular power transmission

Helical Gear Pair

Material : EN24 / EN353

Helix Angle : 15°–30°

Module Range : 2–12

Hardness : 55–62 HRC

Noise Level : Low-noise operation

Applications : Heavy-duty gearboxes, automation

drives